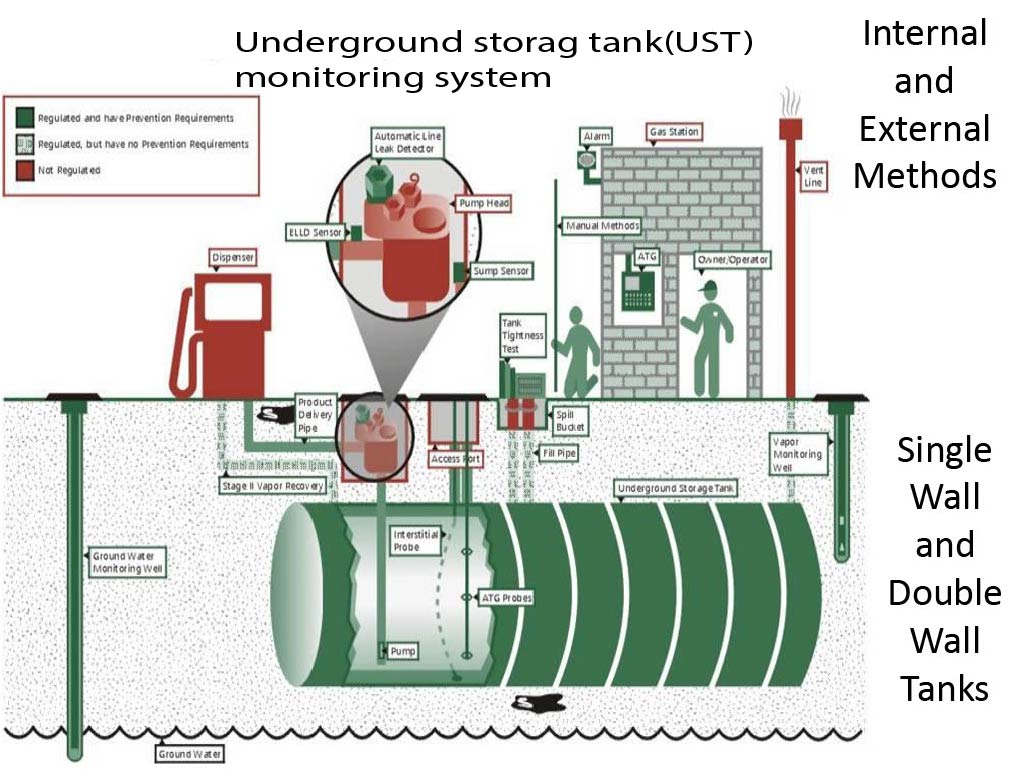

A Veeder Root system is a sophisticated Automatic Tank Gauge (ATG) that can be programmatically configured to oversee various critical aspects related to the utilization, adherence to regulatory standards, and operational efficiency of both aboveground and underground storage tanks.

This advanced monitoring system, developed by Veeder-Root, offers comprehensive capabilities to track and manage crucial parameters such as fuel levels, compliance with industry regulations, and the overall performance of the storage tank. By leveraging automation, the Veeder Root system enhances the precision and reliability of data collection, providing operators with valuable insights to ensure optimal tank functionality and regulatory compliance.

What aspects does a veeder root system monitor | primary fuctions of Veeder root system

Veeder-Root is a company that provides fuel management systems, including tank gauging systems. These systems are designed to monitor various aspects of fuel storage tanks. Here are some key aspects that a Veeder-Root system typically monitors:

- Tank Level: The system monitors the level of fuel in the storage tank. This helps in keeping track of the available fuel and preventing overfills.

- Leak Detection: Veeder-Root systems often include leak detection capabilities to identify any leaks or anomalies in the tank. This is crucial for environmental protection and compliance with regulations.

- Temperature Monitoring: Some systems monitor the temperature of the stored fuel. This information can be important for understanding fuel behavior and preventing issues related to temperature fluctuations.

- Water Detection: Water can accumulate in fuel tanks, leading to corrosion and contamination. Veeder-Root systems can detect the presence of water, allowing for timely corrective action.

- Fuel Dispensing Monitoring: For systems integrated with fuel dispensers, Veeder-Root can monitor the quantity of fuel dispensed, transactions, and ensure accurate record-keeping.

- Inventory Management: The system helps in managing fuel inventory by providing real-time data on fuel levels, transactions, and consumption. This aids in optimizing fuel supply and preventing stockouts.

- Alarm and Notification Systems: Veeder-Root systems are equipped with alarm capabilities. They can generate alerts or notifications for events such as low fuel levels, leaks, or other abnormal conditions, ensuring prompt response.

- Compliance Reporting: Veeder-Root systems assist in generating reports for regulatory compliance, providing documentation for environmental and safety standards.

- Remote Monitoring and Control: Many systems offer remote monitoring capabilities, allowing users to access real-time data and control the system remotely. This is particularly useful for managing multiple fuel storage locations.

- Data Logging and Analysis: The system logs data over time, enabling users to analyze trends, track usage patterns, and make informed decisions about fuel management.

It’s important to note that specific features may vary depending on the model and configuration of the Veeder-Root system in use. Users can customize these systems based on their specific monitoring and management needs.

TLS-450PLUS Automatic Tank Gauge

The Veeder-Root® TLS-450PLUS Automatic Tank Gauge (ATG) provides the most comprehensive site data for advanced fuel asset management. Combining industry leading algorithms with enhanced security, real-time notification, and anywhere anytime access, the TLS-450PLUS keeps your sites running profitably. The TLS-450PLUS is ideal for retail and commercial/industrial applications that have multiple tanks, requiring more than 12 probe and sensor inputs.

https://www.veeder.com/us/automatic-tank-gauging-products/tls-450plus-automatic-tank-gauge

The TLS4 & TLS4B Automatic Tank Gauges

The TLS4 & TLS4B Automatic Tank Gauges for Small Retail, Commercial, & Industrial Applications

The Veeder-Root® TLS4 and TLS4B Automatic Tank Gauges are affordable wet stock management solutions that deliver accurate and crucial information. The TLS4 and TLS4B ATGs are a great way for customers who may be using manual inventory management and reconciliation methods to begin taking advantage of automated reporting.

https://www.veeder.com/us/tls4-tls4b-automatic-tank-gauges

components of a Veeder root system

A Veeder-Root fuel management system is composed of various components that work together to monitor and manage fuel storage. The specific components may vary depending on the model and configuration, but here are the typical elements that make up a Veeder-Root system:

- Tank Monitoring Console (TMC): The TMC serves as the central interface for users to monitor and control the fuel management system. It provides real-time data, alarms, and access to system settings.

- Tank Monitoring Probes: These are sensors or probes installed inside the fuel storage tank to measure parameters such as fuel level, water presence, and temperature. Probes play a crucial role in providing accurate and reliable data.

- Automatic Tank Gauge (ATG): The ATG is a key component that integrates with the tank monitoring probes to measure and display the fuel level, temperature, and other relevant data. It often includes a display screen for local monitoring.

- Leak Detection Sensors: These sensors are designed to detect leaks or abnormalities in the tank. They contribute to environmental protection and help prevent fuel spills.

- Dispenser Interface: For systems integrated with fuel dispensers, there is an interface that monitors and records fuel dispensing transactions. This helps in tracking fuel usage and maintaining accurate records.

- Submersible Turbine Pump Interface: In systems with submersible turbine pumps, there is an interface to monitor pump activity and fuel flow rates.

- Communication Module: Many Veeder-Root systems come with communication modules that enable remote monitoring and control. This can include features like data transmission to a central server, allowing users to access information from different locations.

- Alarm and Notification System: The system includes alarms and notifications to alert users in case of issues such as low fuel levels, leaks, or other abnormal conditions. This ensures prompt action to address potential problems.

- Software Platform: Veeder-Root provides software platforms that allow users to manage and analyze data collected by the system. This includes features for inventory management, compliance reporting, and data analysis.

- Power Supply: The system requires a power source to operate. This can be a standard electrical power connection, and some systems may have battery backup options in case of power outages.

- Accessories and Add-ons: Depending on specific requirements, additional accessories and add-ons may be integrated, such as security features, additional sensors, or communication protocols to interface with other systems.